Camera System Detects Foodborne Toxin

Each year, about 48 million Americans are sickened by foodborne diseases, and 3,000 die, according to the U.S. Centers for Disease Control and Prevention. One factor that limits widespread testing of foods for toxins that cause food poisoning is the cost of equipment.

Chemist Reuven Rasooly and his colleagues at the Agricultural Research Service’s Western Regional Research Center (WRRC) in Albany, California, have developed a simple and inexpensive system for detecting biologically active Shiga toxin, a product of pathogenic Escherichia coli serotype O157:H7. It is estimated that E. coli O157:H7 causes 73,000 cases of food poisoning and more than 60 deaths in the United States each year.

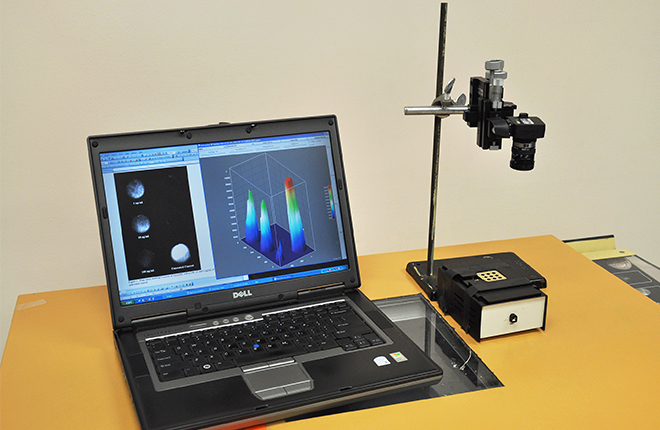

The new system involves the use of a camera and a light-emitting source to biologically determine active toxin. Affordable, sensitive devices like this are needed to reduce the sources and incidence of foodborne illness, says Rasooly, who works in WRRC’s Foodborne Toxin Detection and Prevention Research Unit. Current immunological tests, such as the ELISA, cannot distinguish between the active and inactive form of Shiga toxin.

“For example, in food processing, a heat-treatment method inactivates the toxin, but the ELISA cannot tell whether the toxin is active or inactive in the processed food,” Rasooly says. “Determining the activity of the toxin is very important, because the active form poses a threat to humans. The inactive form is nontoxic.”

Technology used to detect Shiga toxin and other pathogens is expensive and not a concern for resource-rich countries, he says. But equipment is typically too costly for developing countries, where the risk of foodborne illness and outbreaks is greatest. The camera system makes it easy and affordable for diagnostic labs that cannot afford a fluorometer, which is typically used to detect toxins.

“We demonstrated that our system is effective in measuring Shiga toxin activity compared with equipment costing 100 times more,” Rasooly says. “Afluorometer costs about $35,000, whereas the camera in this experiment costs $300.”

In the study, scientists constructed a fluorescence detection system using a camera and light source to measure GFP (green fluorescent protein) in a cell-based assay. A portion of a Shiga toxin-containing food sample was incubated with cells designed to produce GFP. The toxin in the sample inhibited the synthesis of GFP—reducing GFP production in relation to the amount of toxin present. The greater the toxicity, the less fluorescent the cells were.

Filters used with the light source and camera blocked wavelengths (signals) that would interfere with precise measurements of fluorescence. “We obtained these signal levels by taking a picture with a camera and analyzing the image with a free, available computer software that determines average pixel intensity,” Rasooly says.

The camera method, which can easily be adapted for detecting other foodborne toxins,was compared to a commercial fluorometer for detecting active Shiga toxin, Rasooly adds. Both instruments had the same level of toxin detection.—By Sandra Avant, Agricultural Research Service Information Staff.

“Camera System Detects Foodborne Toxin” was published in the September 2015 issue of AgResearch Magazine.

Key Facts

- Foodborne diseases cause sickness in millions of Americans.

- New camera system detects foodborne toxins.

- System is inexpensive and easy to use.

- New system worked as well as the old system.

Full Story