Eastern Regional Research Center

At the Eastern Regional Research Center (ERRC) in Wyndmoor, Pennsylvania, scientists and engineers conduct fundamental, applied, and developmental research on a variety of agricultural commodities. The center finds new uses for staples ranging from milk, meat, poultry, grains, fruits, and vegetables to hides, leather, wools, fats, proteins, and oils. Examples of these innovations developed during the center’s first 60 years can be viewed in the accompanying table.

The center’s research projects provide new applications and technologies aimed at ensuring agricultural products that are of high quality, safe, affordable, and don’t harm the environment. These projects include innovations in feedstock for biofuels, composite materials, functional-food ingredients, and food-safety interventions. Target outcomes include novel antimicrobial and biobased agents for industrial applications, safer food-processing technologies, food-sustaining edible films and packages, and interventions for eliminating contaminants detected via novel methods.

Here are some highlights from the center’s past 15 years.

Producing Bio-oil, a Renewable Biofuel

ERRC scientists have developed methods to turn agricultural biomass byproducts, such as corn and barley residue, into “bio-oil,” which is a renewable transportation fuel. Bio-oil is produced by “fast pyrolysis,” or chemical decomposition of plant matter using high heat. Barley grain, for example, could be used to produce ethanol, a biofuel, which is a fossil fuel alternative, and the byproducts could be used to produce bio-oil. The team recently finished construction of a larger mobile pyrolysis unit capable of processing 2 tons of biomass per day—up from 150 pounds of biomass processed daily using the older bench-scale unit.

Model Helps Reduce Greenhouse Gas Emissions

On farms, activities involved in milk production generate greenhouse gas emissions due to methane from cows and manure. Off farms, activities such as processing, packaging, and refrigerating milk also generate greenhouse gas emissions due to energy use. ERRC scientists and partners created a computer-based model to help processors lower their energy use, which lowers greenhouse gas emissions. The model offers multiple ways of making changes in individual processing plants and instantly calculates both greenhouse gas reductions and costs of implementing the changes. The model has been distributed to more than 100 U.S. processors to help the dairy industry realize its goal of reducing greenhouse gas emissions by 25 percent per gallon of milk by 2020.

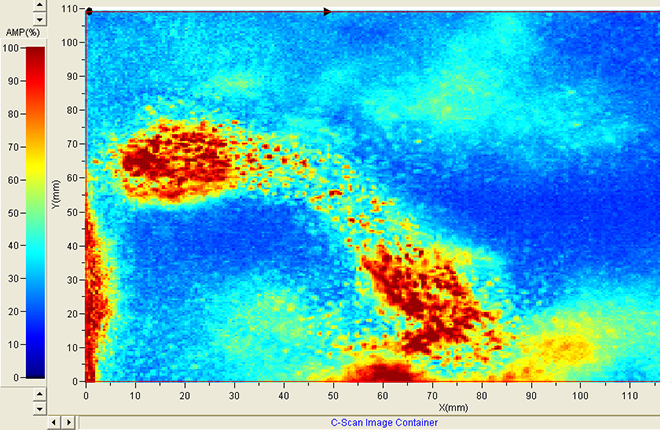

Ultrasound Method To Inspect Hides and Leather

Leather is an important utilization product because it is based on processing waste and yields numerous economic benefits. The U.S. beef industry produces about 35 million cattle hides annually, and these hides are visually inspected and ranked for quality and sale price. But when hair is present on the hides, visual inspection is unreliable in terms of detecting defects. An objective and nondestructive method to accurately evaluate the quality of hides is needed at the earliest stage of processing. ERRC scientists developed techniques to use airborne ultrasonic imaging that can reveal the presence of defects in hides and leather. Using the ultrasound imaging method provides the industry with a new means to assess and grade raw hides and leather.

Detecting and Isolating Escherichia coli

Toxin-producing E. coli serotype O157:H7 is a well-known foodborne pathogen. These bacteria have many cousins (different strains), including a group called the “Big Six,” which have also been linked to outbreaks of foodborne illness. ARS researchers developed an award-winning analytical method that tests for all seven serogroups. The method is based on the polymerase chain reaction, followed by isolation and confirmation using a latex agglutination method. The technologies are key components of commercialized test kits that are being used by the U.S. Department of Agriculture’s Food Safety and Inspection Service.

Reducing Pathogens and Increasing Food Safety

At the request of U.S. regulatory agencies, ERRC researchers conducted a comprehensive survey of retail ready-to-eat foods (defined as deli meats, soft cheeses, raw and smoked fish, and raw or partially processed vegetables). The award-winning study provided data critical for developing a risk assessment and controlling the bacterium Listeria monocytogenes. ERRC researchers also are working on using ionized gas molecules, also known as “non-thermal plasma” or “cold plasma,” to kill microbes on meats, poultry, fruits, and vegetables. The cold plasma work has produced significant, multi-log reductions in E. coli, Salmonella, and Listeria, and next-step developments are in the works.

Improving the Safety of Powdered Infant Formula

Cronobacter sakazakii is a foodborne pathogen that has been found in some dry foods, including dehydrated powdered infant formula. ERRC scientists investigated the growth of C. sakazakii in reconstituted powdered infant formula and developed predictive models. These models assist regulatory agencies in conducting risk assessments of reconstituted powdered infant formula exposed to various conditions and help parents and other caretakers to properly store and prepare reconstituted powdered infant formula.

Detecting and Eliminating Residues

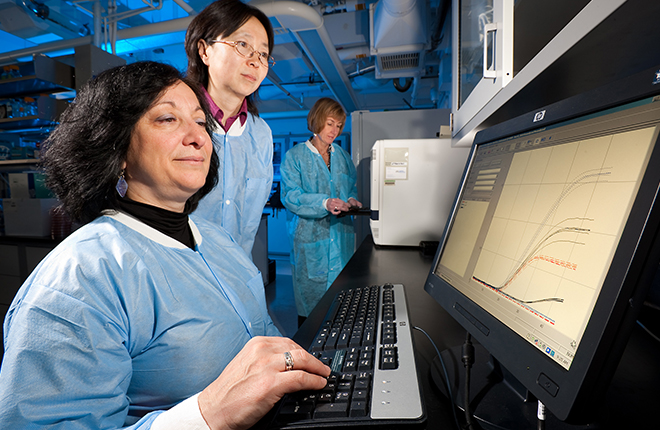

ERRC scientists and colleagues have developed advanced methods to detect chemical residues, such as veterinary drugs and pesticides, and also pathogenic bacteria and their toxins in food products. One of their newer methods is called “QuEChERS,” which stands for “quick, easy, cheap, effective, rugged, and safe.” This method makes it easier and less expensive for analytical chemists to examine for example fruits and vegetables for pesticide residues.

ERRC scientists have won numerous national and international awards for their work, including the 2007 designation by the American Chemical Society as a National Historic Chemical Landmark, recognizing ERRC scientists’ development of the dehydration technology that resulted in reconstituted instant mashed potatoes.—By Rosalie Marion Bliss, Agricultural Research Service Information Staff.

“Eastern Regional Research Center, Wyndmoor, Pennsylvania” was published in the October 2015 issue of AgResearch Magazine.

Key Facts

- Eastern Regional Research Center.

- Located in Wyndmoor, Pennsylvania.

- Develops new and improved uses for animal byproducts, such as milk, hides, and wool.

- Also has research projects on bioenergy, food processing, and food safety.

Full Story