Western Regional Research Center

Scientists and engineers at the Western Regional Research Center (WRRC) have made pivotal discoveries and developed a diverse set of technologies that over the years have played key roles in food and flavor research, improved the lives of consumers, and spurred innovations that can be seen on today’s supermarket shelves. (See table.)

In more recent times, some WRRC researchers have focused their efforts on the needs of people in the West, such as helping food processors save water and property owners safeguard their homes from wildfires. Others have addressed more universal goals, such as helping consumers stay healthy.

Saving Water in Food Processing

California is now known as a drought-stricken state, but it also produces the majority of the nation’s processed tomatoes. Many tomato processors use either steam or a chemical-based process to remove peels from Roma-style tomatoes. The problem is that those processes use a lot of water and often damage the tomatoes.

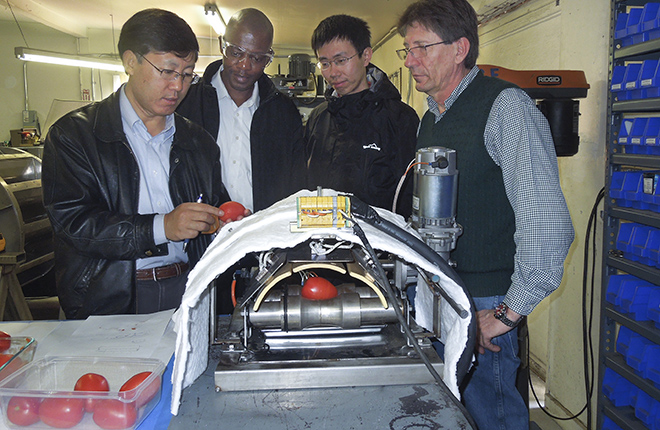

WRRC engineers have come up with a way for food processors to save water when peeling tomatoes—and possibly other fruits and vegetables as well.

The approach taps the potential of infrared energy, now used in some high-end commercial ovens. At the processing facility, tomatoes traveling on conveyor belts are heated for about 60 seconds with infrared emitters placed alongside the belts. The heat loosens and cracks the peel, making it easier to split when the tomatoes go through a vacuum chamber, where the peels are automatically removed by a roller. The researchers refined the steps in more than 5 years of testing involving about 6,000 commercially grown Roma-style tomatoes. Tests show the process could also be used to peel peaches and pears.

The infrared process is mostly waterless, so there is significant water savings. It also eliminates the problem of properly disposing of wastewater in the chemical process, where water is mixed with sodium hydroxide or potassium hydroxide. The new process is also easier on the structure and texture of the tomatoes so that they stay firm and are less likely to fall apart when cut. The engineers have patented the technology and published studies on it. They also are working with Precision Canning Equipment of Woodland, California, and Del Monte Foods of Walnut Creek, California, to commercialize the process, which has been successfully evaluated on an experimental pilot system.

Mushrooms With Vitamin D

Many health-conscious people are concerned about getting sufficient amounts of vitamin D, which is essential for healthy bones and comes from meats and fortified milk, but mostly from exposure to sunlight. Until a few years ago, mushrooms seemed like an unlikely source for it. Mushrooms are usually grown in the dark and typically have low levels of the nutrient.

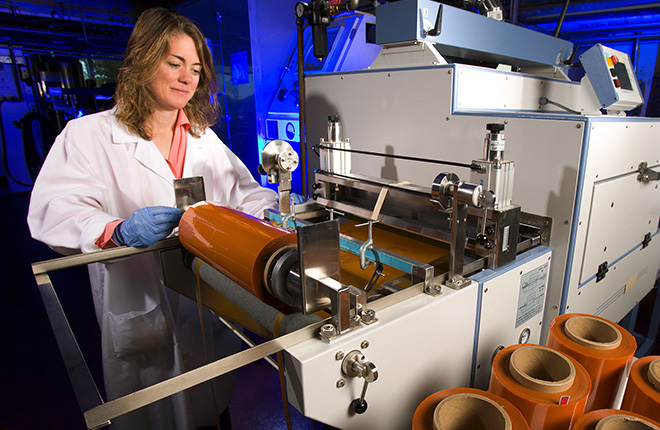

WRRC food technologists have found a way to boost levels of vitamin D in mushrooms. Their work followed the discovery several years ago by other scientists that exposing mushrooms to sunlight boosted levels of the nutrient. A compound in mushrooms, known as “ergosterol,” is converted into vitamin D when exposed to the UV-B light in sunlight. The problem is that in nature, it takes several hours. The conversion occurs naturally, but it takes too long to be practical for mushroom processors.

WRRC researchers began working with Monterey Mushrooms of Royal Oaks, California, to find a way to give mushrooms a sufficient dose of UV-B light to boost vitamin D levels. They needed to speed up the process, make it cost effective, and make sure it didn’t degrade the quality of the mushrooms.

The resulting technology, now used in all of Monterey’s mushroom processing, exposes mushrooms to UV-B light for a few seconds, so that the mushrooms provide 100 percent of the Recommended Dietary Allowance (RDA) of vitamin D in every 3-ounce portion. Monterey Mushrooms promotes the vitamin D enrichment in its white, baby portabella, and large portabella mushrooms.

Testing for Botulism

Concerns about public health and botulism outbreaks motivated WRRC biologists to develop a test strip for detecting the deadly bacterial toxin in a blood sample.

Botulism is caused by the improper processing of foods and the improper storage of meats. It is the most toxic natural substance known; it is often fatal, and patients who survive are sometimes hospitalized for months. Health officials currently detect botulism by running tests for the toxin on a suspected food source or a patient’s blood or stool sample, and results can take several days. Early detection is important so that the source of an outbreak can be identified and additional cases prevented.

The strip developed by WRRC scientists can provide same-day detection. The strip could also be used by police, fire, and military personnel in the event of a bioterrorism attack. No one has licensed the strip yet, but the results show that it is as sensitive as current testing methods—and a lot faster. Other companies make strips, but this strip is 100- to 1,000-fold more sensitive.

Protecting Homes From Wildfires

In a state prone to wildfires, WRRC scientists have developed a fire-retardant gel for spraying on houses threatened by a wildfire. It offers better and more affordable protection than commercial gels made from other compounds.

The gel, made of sodium bentonite clay, cornstarch, and water, could be applied just hours or days before a fire with spraying equipment now on the market. It could be used to protect mountain retreats, cabins, or other wooden structures. Tests showed that the gel held in moisture longer than other fire treatments and that wood treated with it took longer to reach 392 ˚F, the temperature at which wood siding may begin to burn or char. It can be applied quickly, washes off easily, is biodegradable, and is less prone to sliding down a vertical surface.

WRRC scientists have published several papers on their results, patented the technology, and are seeking a commercial partner. They see a potential market in municipalities and property owners in areas prone to wildfires.

“Whether it’s wildfires, water shortages, or human health, our scientists and engineers have a history of addressing issues of public concern and developing practical and sustainable technologies that will help consumers, food processors, growers, and others. As we look to the future, we remain committed to continuing that work and to coming up with solutions to the challenges we face in an ever-changing world,” says Howard Zhang, WRRC center director.—By Dennis O’Brien, Agricultural Research Service Information Staff.

“Western Regional Research Center, Albany, California” was published in the October 2015 issue of AgResearch Magazine.

Key Facts

- Western Regional Research Center.

- Located in Albany, California.

- Research on weeds, wheat, and potato breeding and their byproducts; crop improvement and genetics; and control of exotic and invasive weeds.

- Also has research projects on bioenergy, food processing, and food safety.

Full Story