How to Make a Wave Behave

In the lower Mississippi Delta, farmers often build ponds for aquaculture and for storing surface water to irrigate crops. But erosion generated by wind-driven waves can reduce reservoir levee widths by a foot every year, and repairs can be needed as soon as 5 years after a reservoir is completed.

It’s not simple—or cheap—to patch up a reservoir with silt loam levees that can stretch over a mile and that are 25 to 30 feet wide. The costs can average $3 per foot, which adds up to around $15,000 per structure.

People have tried to stabilize the levees with tires, construction materials, or vegetation, but hydraulic engineer Daniel Wren is experimenting with another approach. “We wanted to see if we could find a way to cut down on the erosive energy hitting the levees,” he says.

Wren, who works at the Agricultural Research Service’s Watershed Physical Processes Research Unit in Oxford, Mississippi, partnered with ARS hydraulic engineer Carlos Alonso (now retired) and University of Mississippi research associate Yavuz Ozeren for his research. The team gathered data about wind and wave dynamics from a 70-acre irrigation reservoir in Arkansas. Then they took their data into the lab and designed several wave barriers that they tested in a 63-foot-long wave flume.

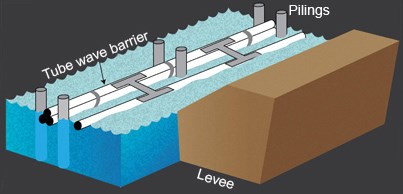

Lab results indicated that a floating barrier held in place by two rows of pilings would provide the most effective embankment protection from wave action (see diagram).

The barrier was made of a 9½-inch-diameter tube that was attached to a 4¾-inch-diameter tube with a 24-inch length of smaller tubing. Since it was confined between the two rows of pilings, the barrier was able to rise and fall with fluctuating water levels—unlike a barrier tethered to the bottom of the pond, which might end up below the water surface as reservoir levels rise.

The team found that this two-tube barrier was able to dissipate 75 percent of wave energy for waves within the design range before they washed against the levees. The waves lost some of their force when they broke against the first tube and then lost even more energy as they broke against the second tube.

Wren’s team calculated the costs of using different materials for constructing the wave barriers, including the logistics of transporting materials to the site and the labor involved in assembling and installing the barriers. A key to the barrier’s effectiveness was its total combined diameter. The engineers found that bundling several lengths of smaller tubing together to obtain an optimal diameter worked as well as one tube with a larger diameter. And transportation costs were lower for the smaller tubing.

“The cost savings could be significant when you need to protect several hundred yards of levees,” Wren observes.—By Ann Perry, Agricultural Research Service Information Staff.

This research is part of Water Availability and Watershed Management, an ARS national program (#211) described at www.nps.ars.usda.gov.

Daniel G. Wren is with the Watershed Physical Processes Research Unit, USDA-ARS National Sedimentation Laboratory, 598 McElroy Dr., Oxford, MS 38655; (662) 232-2926.

"How to Make a Wave Behave" was published in the July 2010 issue of Agricultural Research magazine.